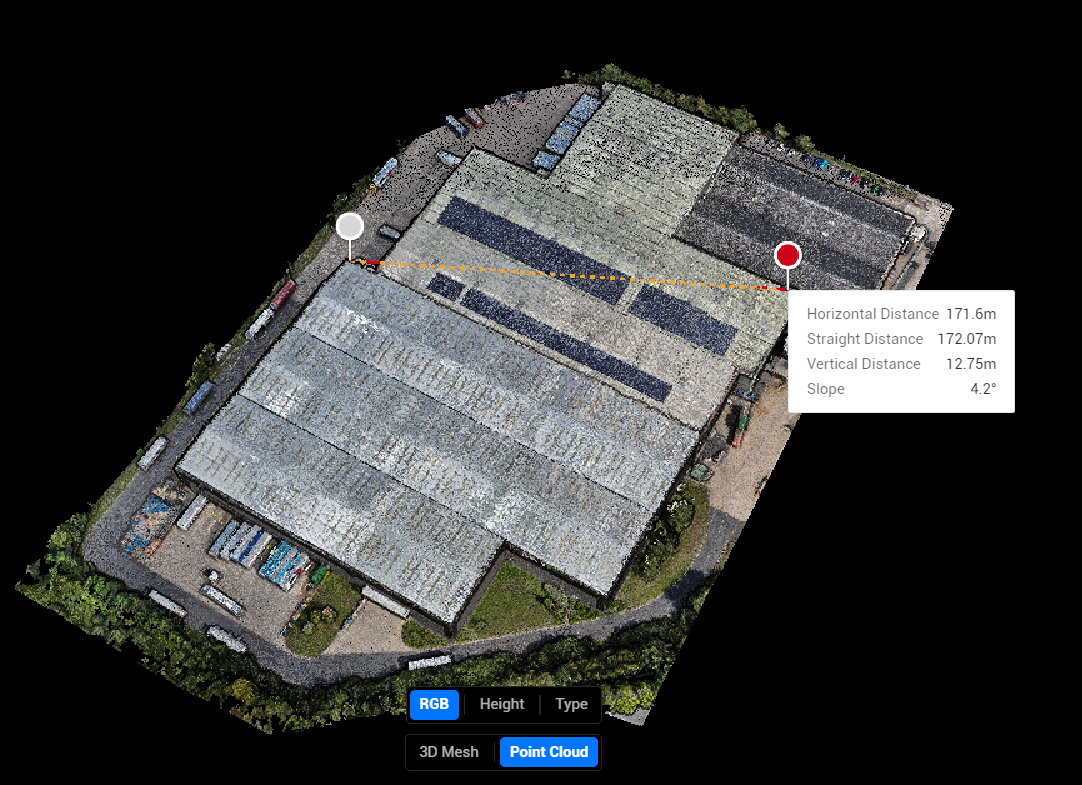

Logistics Centre Survey

Roof Measurements and Inspection Photography

Overview

The client had a specific section of the roof that required accurate measurements to assess asbestos removal. They also required aerial photography and video footage to carry out a roof condition inspection on a single building in a multi building complex'.

Sector - Logistics Centre

Output - 3D model, High resolution grid photo sets, Video footage of specific roof section

Location - Nottinghamshire

Delivery - June 2025

Drone Data Capture Method

1. Office Preparation

Checked airspace restrictions and confirmed required authorisations & permissions

Completed pre-flight assessments in line with CAA requirements

Planned the mission route, including flight altitude, speed, ground sampling distance (GSD) and area coverage using DJI Pilot 2

2. Pre-Flight Planning:

Conducted an initial reconnaissance flight to verify site conditions, obstacles and lighting.

Refined the survey area in the controller on site, adjusting the altitude slightly to avoid additional hazard (chimney section).

Ensured adequate photo overlap (80/80) to give high accuracy to the final deliverables.

Confirmed RTK GPS fix for centimeter-level accuracy.

3. Drone and Sensor Setup:

Configured camera:

The M4E uses a mechanical shutter to eliminate motion distortion.

Set shutter speed 1/1000 sec to minimize blur.

Shot in RAW & high-quality JPEG.

Set ISO to auto.

4. Flight and Image Acquisition:

Flew the programmed mission capturing overlapping images from nadir (top-down) and oblique angles to cover all roof planes, ridges, valleys, chimneys and details.

Captured close-up images of specific roof section using the M4E high-res grid mode as required by the client.

Manually flew the drone over the required roof section at different angles and altitudes to capture the roof section. Also took cloesup video footage using the M4E's zoom lenses to capture specific details.

Used RTK positioning throughout all flight to ensure geospatial accuracy.

5. Post-Flight Quality Review:

Checked images and video footage for clarity, completeness and overlap.

6. Data Processing:

Imported images into DJI Terra

Generated 3D model of the roof.

Extracted precise roof measurements of particular roof section (length, area, pitch).

Annotated and documented inspection findings.

Processed high-res grid mode shots.

Processed all video files.

7. Reporting and Delivery:

Provided georeferenced 3D model and point cloud in client-compatible formats.

Uploaded all data and pictures to Nira, providing the client an online resource to visualise and review.

Delivered high-res grid photos for closer inspection purposes and video footage of the roof section via password protected Dropbox

Benefits

Enhanced Decision-Making

Collected visual and measurement data can be analysed remotely by specialists to develop safe and effective asbestos removal plans and maintenance schedules without repeated site visits.

Minimal Disruption

Inspections can be carried out while the site operates normally, important in multi-building complexes to avoid disrupting tenants or commercial activity.

Comprehensive Inspection

Drones can cover the entire roof surface, including difficult-to-access areas and capture detailed condition imagery. This allows thorough identification of damage, wear, asbestos presence, or structural issues without physical access.

Accurate and Detailed Data

High-resolution aerial images and measurements provide precise roof dimensions essential for planning asbestos removal accurately. This reduces the risk of estimation errors that could lead to cost overruns or incomplete removal.

Safety

Using drone photography avoids sending surveyors onto potentially hazardous roofs containing asbestos. This minimises the risk of disturbing asbestos fibres and exposure to harmful materials, protecting workers and occupants alike.

Efficiency and Cost-Effectiveness

Drone inspections are faster, require less manpower and do not need expensive scaffolding or roof access equipment. This saves time and lowers overall project costs while minimising disruption to the site.